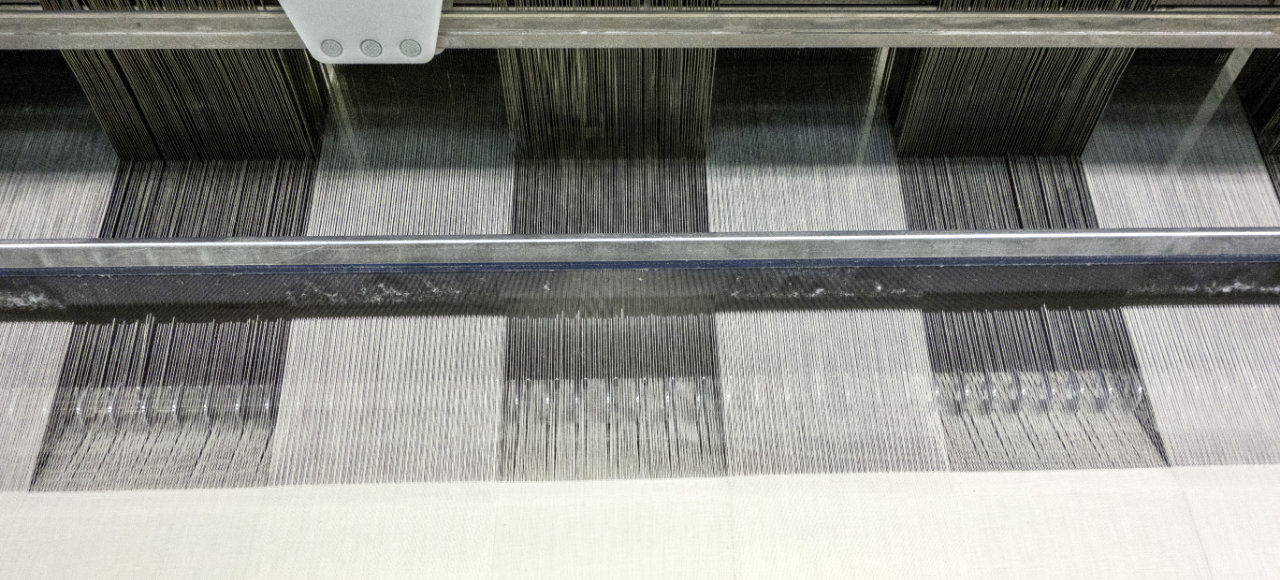

Weaving the Organic Cotton Yarns

Cotonea organic textiles are woven in our own weaving factory in the Czech Republic and by our partners. Best organic quality and the highest standards for natural textiles are of high importance.

The Weaving Factory Further Work Stages