Refining and finishing the organic cotton textiles

Refinement of the raw organic textiles in Germany or Switzerland according to the highest standards, without the use of dangerous or harmful chemicals.

Refining and finishing Further work stages

Refinement of the raw organic textiles in Germany or Switzerland according to the highest standards, without the use of dangerous or harmful chemicals.

Refining and finishing Further work stagesTo control and monitor refinements, immense knowledge and great time and expense is necessary. The standards IVN BEST or GOTS that were chosen by us are very useful, as these two standards provide lists on which substances that are completely non-hazardous according to current knowledge, are noted. Every manufacturer of a substance must apply for the approval to be included on this positive list and reveal all their formulas. The standards take both into account for the evaluation of, on the one hand the health safety of the person who wears or works with the textile, as well as on the other hand the impact on the environment during processing.

If you find the notice “wash before wearing” on a textile, presumably problematic substances were used during the refinement of the material, which have not been washed out due to cost-cutting. The customer has to take over this task.

Our Cotonea textiles and fabrics are refined solely in Germany and Switzerland, as it is guaranteed here, that the demanding guidelines of IVN Best, or the guidelines of the less demanding GOTS, are fulfilled. For us, the largest part of refinement is bleaching, dyeing or printing. The fine flannelette and molleton fabric are mechanically roughened, this way they receive their soft and moisture absorbing surface. All our fabrics are mechanically pre-shrunk, so that they only minimally shrink after washing. We forego the use of, for example, “non-ironing” or “easy-ironing” textiles completely. To give a textile this characteristic, you need chemicals that are always banned according to IVN Best guidelines and mostly prohibited according to GOTS guidelines, furthermore, the cotton’s natural properties are lost to a great extent.

Manufacture of products using Cotonea organic textiles in our own sewing workshop in the Czech Republic.

Find out more

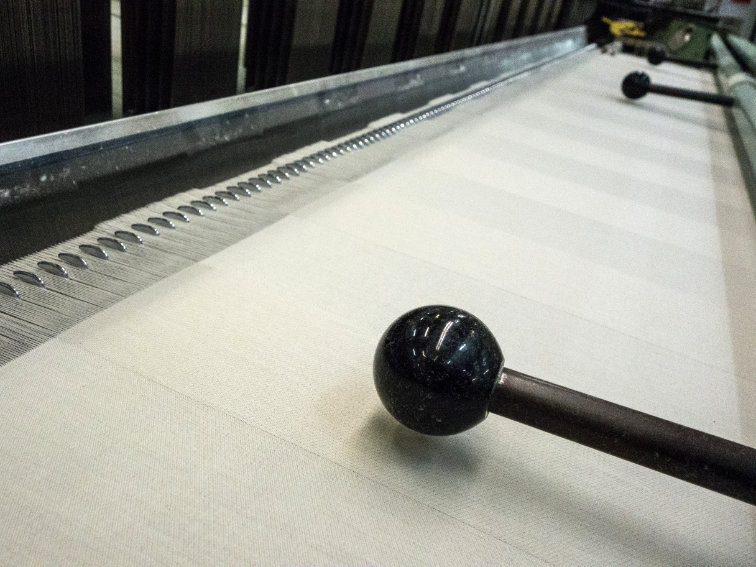

Cotonea organic textiles are woven in our own weaving factory in the Czech Republic by our partners.

Find out more