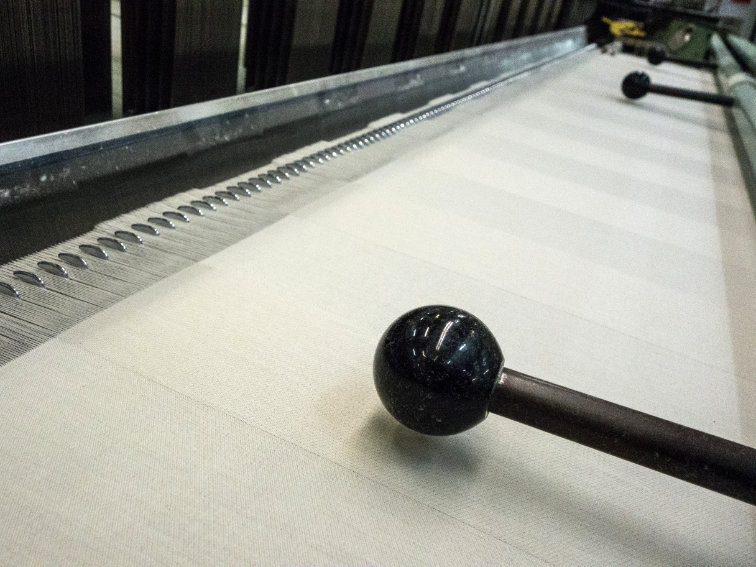

The Manufacturing of Cotonea’s Organic Textiles

Harmful substances or substances of concern must not be used anywhere during the production process. Working conditions and wages are fair - because we want it that way.

General Information Production Chain